Call us at (650) 856-8833 or email us at Sales@StcValve.com.

Stainless Steel Push-In Fittings Specifications

- Installation of Pipe Fittings

-

Tighten fitting by hand, then turn it 2-3 turns with a wrench

until it reaches the desired torque listed. If the fittings are not

pre-coated with sealant, or is used and the sealant is not in good condition,

apply Teflon sealant tape to the threads.

Recommendation of Torque for Tightening Fittings Fitting Thread Size Torque, lb-ft Torque, kgf/cm 10-32, M5 - M6 1.0 - 1.5 14 - 21 NPT 1/8, R1/8 5 - 6.5 70 - 90 NPT 1/4, R1/4 8.5 - 10 120 - 140 NPT 3/8, R3/8 16 - 17.5 220 - 240 NPT 1/2, R1/2 20 - 21.5 280 - 300

-

Tighten fitting by hand, then turn it 2-3 turns with a wrench

until it reaches the desired torque listed. If the fittings are not

pre-coated with sealant, or is used and the sealant is not in good condition,

apply Teflon sealant tape to the threads.

- Installation of Tubing into Fitting:

- Slowly push a clean and perpendicularly cut tube into the fitting until it comes to a dead stop.

- Gently pull the tubing back until the Grip Ring or Collet of the fitting grips onto the tubing and has a good seal.

- Use Polyethylene, Polypropylene, Polyurethane, or Nylon tubing designed for instant fittings.

- Hard metal tubing can be used for all metal Stainless Steel if the tubing is pre-grooved.

- Removal of Tubing from Fitting:

- Push in evenly on the Release Button.

- Pull out the tube while depressing the Release Button.

- To reuse the tubing, cut off the lodged portion of the previously used tubing in an even and perpendicular fashion.

- Recommended Tubing Material, Size, and Hardness Requirements:

Tubing Material Specified Size Hardness (Durometer) Polyurethane +/- 0.006" (+/-0.15 mm) Shore A 85 or higher Polyethylene +/- 0.004" (+/-0.1 mm) Shore D 44 - D75 Polypropylene +/- 0.004" (+/-0.1 mm) Shore D 44 - D75 Nylon +/- 0.004" (+/-0.1 mm) Shore D 44 - D75 Pre-grooved Metal Tubing +/- 0.004" (+/-0.1 mm) - Storage:

- Store fittings in a dry, cool place away from sunlight.

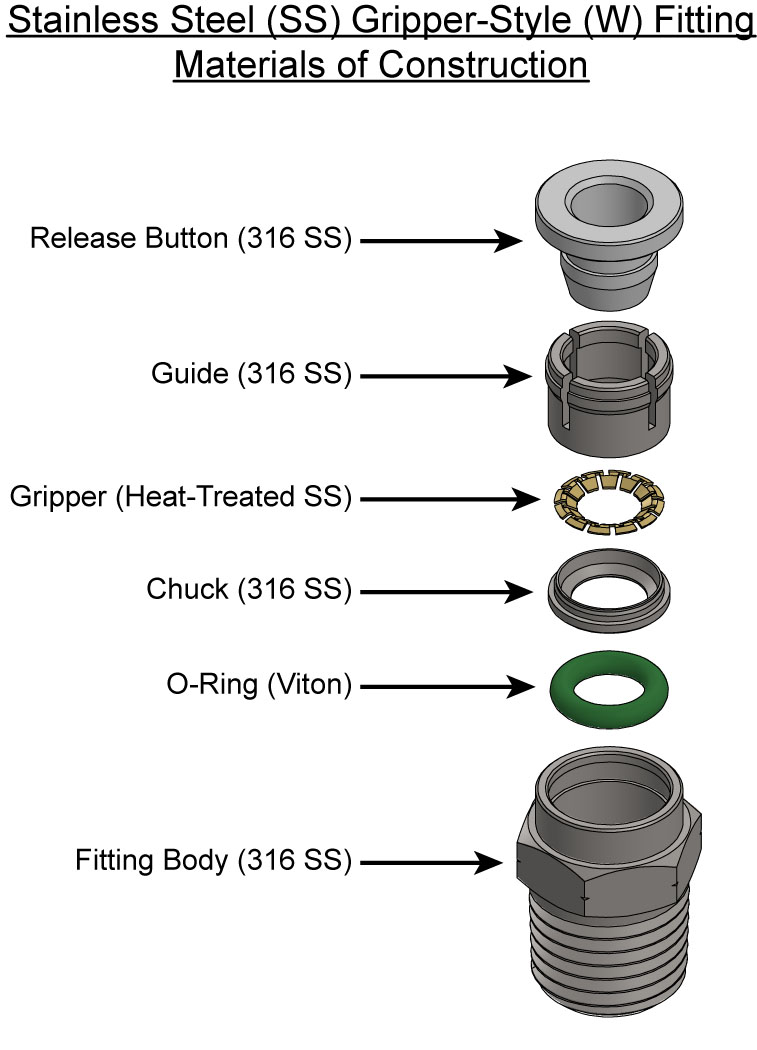

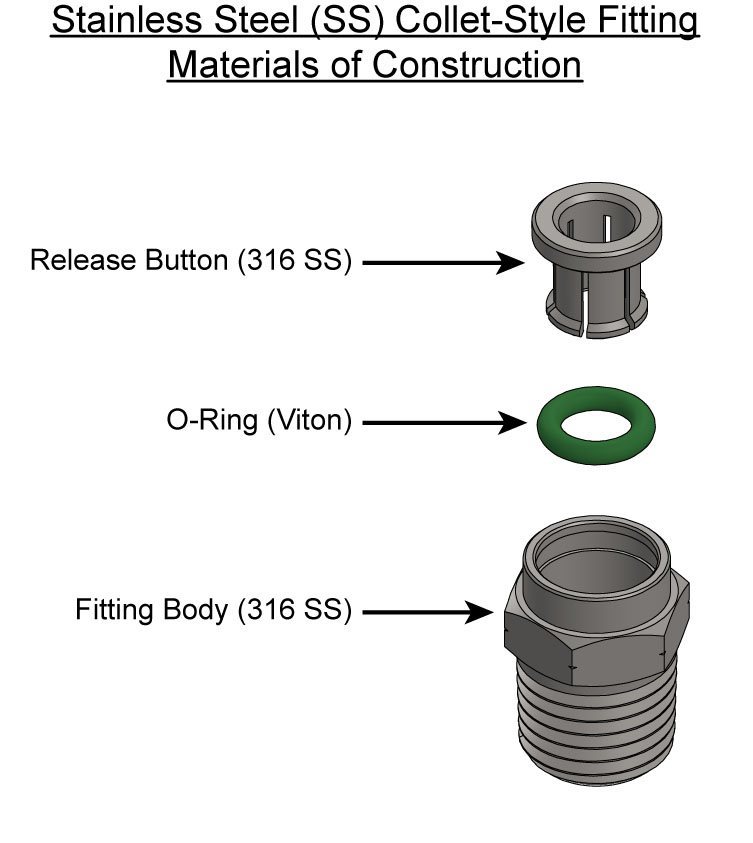

- Specifications, Materials of Construction, and Schematic of Typical Construction:

Specifications Operating Pressure Range 0 - 250 PSI (0 - 1650 kpa)

Option: 1000PSIVacuum 0 - 30" Hg (760 mm Hg) Operating Temperature 5 - 230°F (-15 to 110°C) Recommended Tubing Material Polyurethane, Nylon, Polyethylene, Polypropylene, and pre-grooved hard metal tubing Metal Body T316 Stainless Steel Plastic Body None Release Button 316 Series Stainless Steel Grip Ring or Collet 316 Series Stainless Steel O-Ring Viton Thread Sealant None Service Air, Liquid Sterilization Temperature Up to 280°F (138°C)

| Home | Terms of Use | Terms of Sale | Career | Contact Us | Click Here to Order |

|

Sizto Tech Corporation © 2001-. All rights reserved. Last modified: February 20, 2017.

Information contained herein may be changed without prior notification. |

|||||