Call us at (650) 856-8833 or email us at Sales@StcValve.com.

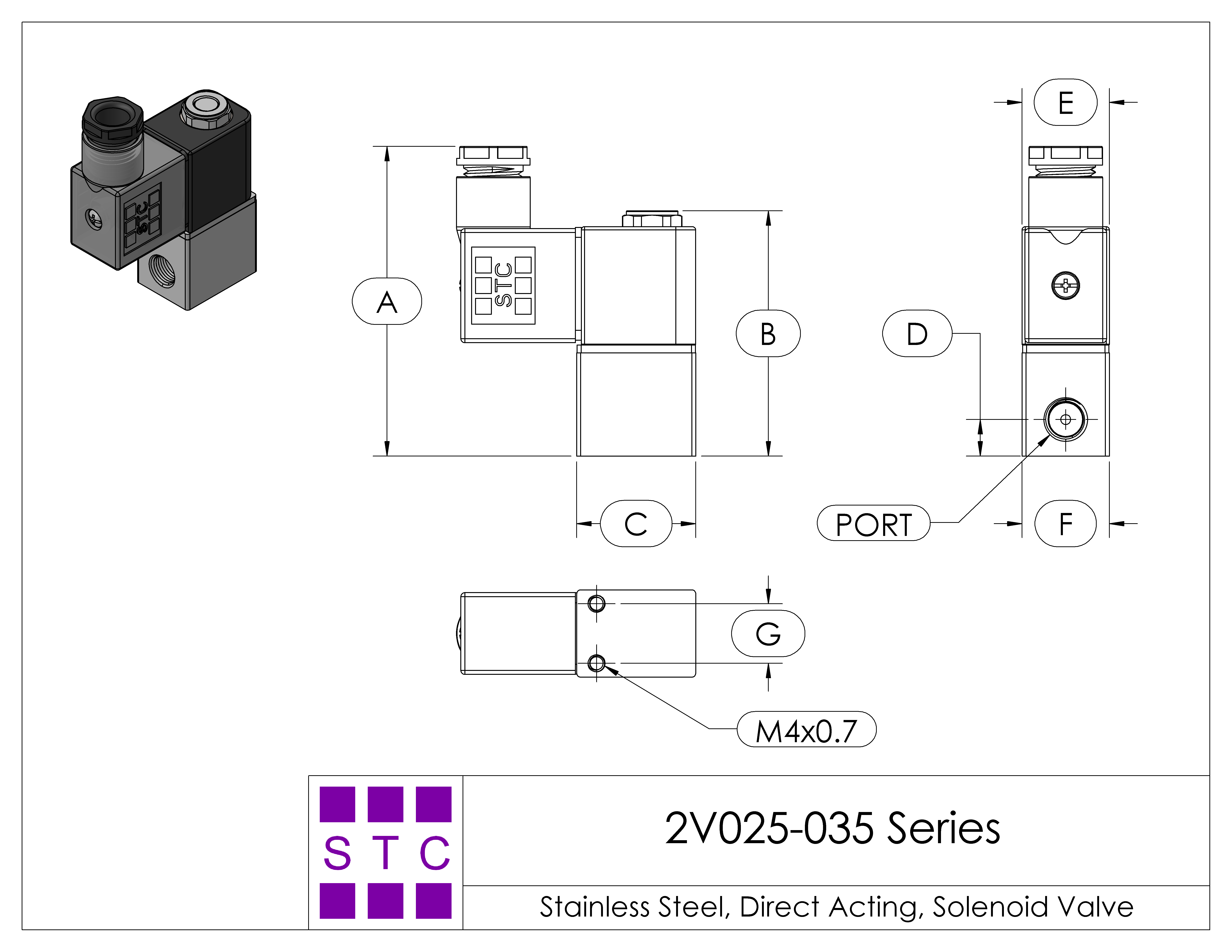

Solenoid Valve Specifications and Dimensions: 2V025-035 Series

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

To Connect the Valve Inlet & Outlet:

• Connect the inlet & outlet to the valve ports according to the flow direction arrow marked on the valve

To Install the Coil:

• Put the coils on to the armture tube of the valve. Place the lock washer & nut on to the armature tube. Hand tighten the nut, then use a wrench to tighten the nut another quarter-turn. Do not over-tighten the nut, as it may cause the armature tube to fail prematurely.

To Connect a DIN Coil:

1. Remove the Philips-head screw from the plastic DIN housing & unplug it from the DIN coil.

2. From the screw opening, push the terminal block out from the plastic DIN housing.

3. Note the “1”, “2”, and ground “⏚” symbols on the underside of the DIN enclosure.

4. For DC DIN Coils, connect “1” to your Positive Lead & “2” to your Negative lead.

5. For AC DIN Coils, connect “1” to your HOT lead, “2” to your Neutral lead, & “⏚” to your ground if required.

Do not energize the coil without installing it onto the valve or connect the coil to a different voltage than specified. This will burn the coil and could create fire hazards.

Safety Note: Standard valves are supplied with continuous duty coils. The proper class of insulation for the service is indicated on the coil body. The coil temperature may rise significantly if energized for extended periods—this is normal. Although the coil is made of flame-retardant material, misuse of the coil could create fire hazards & generate smoke and/or a burning odor. If these conditions are encountered, the coil temperature has risen above safe levels and the power should be disconnected immediately.

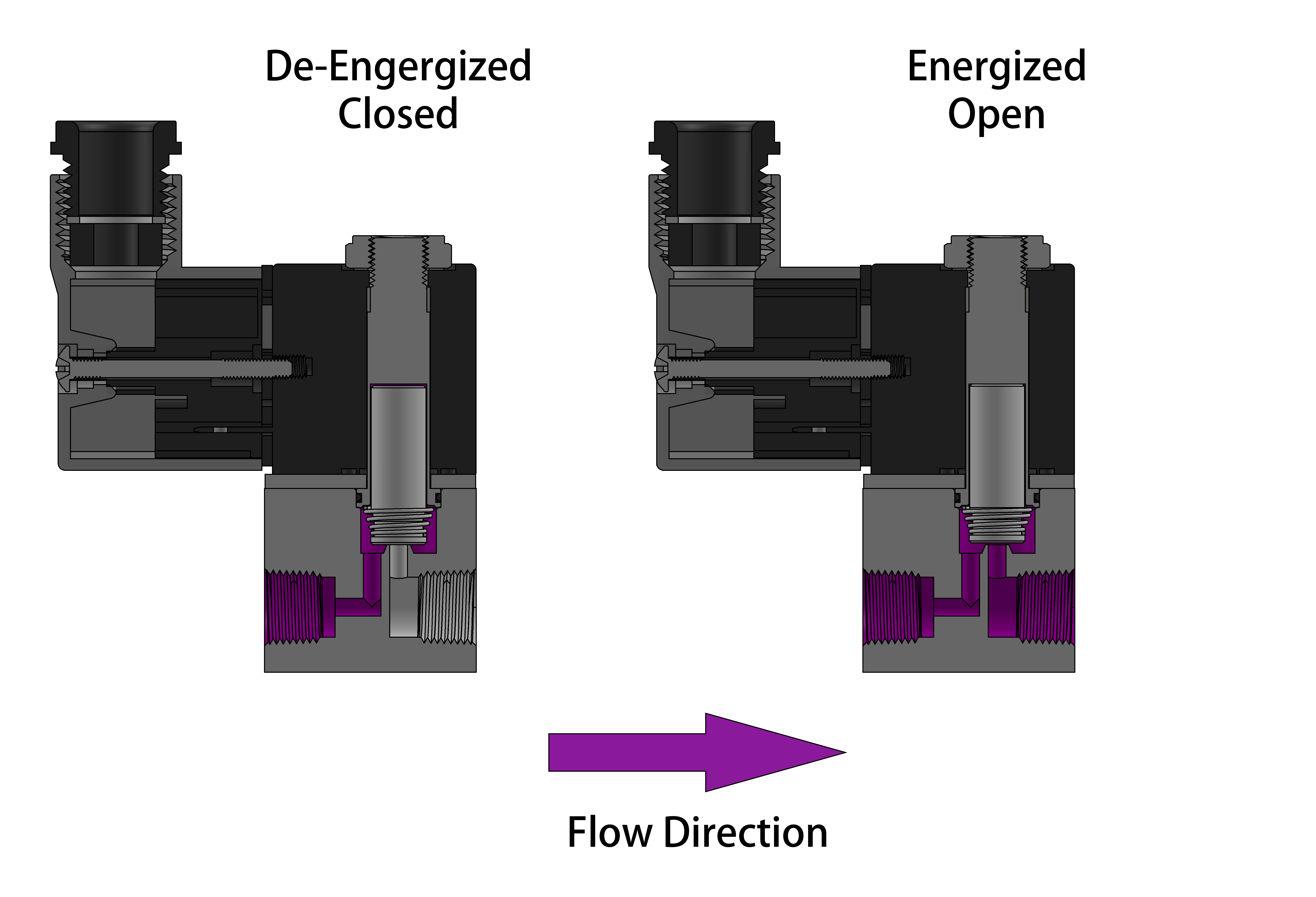

Operation: The 2V025 series solenoid valve is a direct acting valve & does not require a minimum differential pressure to operate. The cross-section below shows the valve in a closed (de-energized) state. When energized, the plunger directly lifts the isolated diaphragm, allowing the working medium to pass through the valve orifice. When de-energized the spring force returns the diaphragm to the valve orifice & seals the valve.

• Connect the inlet & outlet to the valve ports according to the flow direction arrow marked on the valve

To Install the Coil:

• Put the coils on to the armture tube of the valve. Place the lock washer & nut on to the armature tube. Hand tighten the nut, then use a wrench to tighten the nut another quarter-turn. Do not over-tighten the nut, as it may cause the armature tube to fail prematurely.

To Connect a DIN Coil:

1. Remove the Philips-head screw from the plastic DIN housing & unplug it from the DIN coil.

2. From the screw opening, push the terminal block out from the plastic DIN housing.

3. Note the “1”, “2”, and ground “⏚” symbols on the underside of the DIN enclosure.

4. For DC DIN Coils, connect “1” to your Positive Lead & “2” to your Negative lead.

5. For AC DIN Coils, connect “1” to your HOT lead, “2” to your Neutral lead, & “⏚” to your ground if required.

Do not energize the coil without installing it onto the valve or connect the coil to a different voltage than specified. This will burn the coil and could create fire hazards.

Safety Note: Standard valves are supplied with continuous duty coils. The proper class of insulation for the service is indicated on the coil body. The coil temperature may rise significantly if energized for extended periods—this is normal. Although the coil is made of flame-retardant material, misuse of the coil could create fire hazards & generate smoke and/or a burning odor. If these conditions are encountered, the coil temperature has risen above safe levels and the power should be disconnected immediately.

Operation: The 2V025 series solenoid valve is a direct acting valve & does not require a minimum differential pressure to operate. The cross-section below shows the valve in a closed (de-energized) state. When energized, the plunger directly lifts the isolated diaphragm, allowing the working medium to pass through the valve orifice. When de-energized the spring force returns the diaphragm to the valve orifice & seals the valve.

| Operation Diagram | ||||||

|

| Home | Terms of Use | Terms of Sale | Career | Contact Us | Click Here to Order |

|

Sizto Tech Corporation © 2001-

. All rights reserved. Last modified: February 11, 2019.

Information contained herein may be changed without prior notification. |

|||||