Call us at (650) 856-8833 or email us at Sales@StcValve.com.

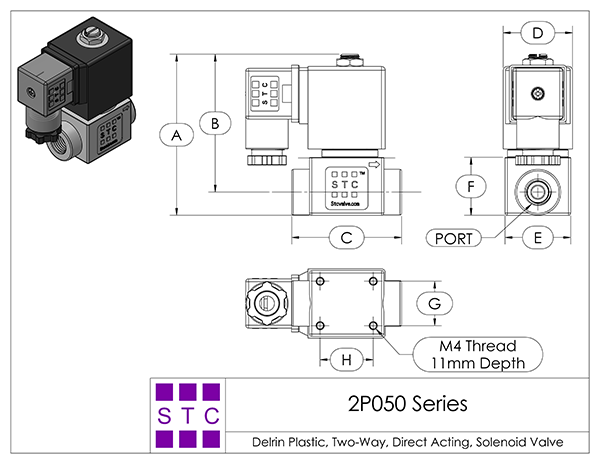

Solenoid Valve Specifications and Dimensions: 2P050 Series

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The 2P050 valve is a two-way, normally closed, direct acting

valve and does not require a minimum differential pressure to operate. As

shown in the diagrams below, when the coil is de-energized (left diagram),

the plunger rests on the main orifice and is held in place by the plunger

spring force, sealing the valve. When the coil is energized (right diagram),

the solenoid lifts the plunger and allows the working medium to flow through

the orifice. The working medium and flow direction are indicated in purple

in the diagrams.

Benefits:

Benefits:

- Can be used in food grade, sanitary, and chemical applications.

- The valve body can be customized to any type of plastic to meet specific operating conditions.

- Double Viton O-ring for improved sealing at the tube inlet and outlet.

- The threaded armature top screws into the armature tube, and then the connection is welded together. The threaded connection combined with welding allows for a longer lifespan of the valve.

- The armature tube is machined from a solid stainless steel bar - with no additional joints or connections, it can withstand higher pressure and more lifecycles.

| Operation Diagram | ||||||

|

| Home | Terms of Use | Terms of Sale | Career | Contact Us | Click Here to Order |

|

Sizto Tech Corporation © 2001-

. All rights reserved. Last modified: February 11, 2019.

Information contained herein may be changed without prior notification. |

|||||