Call us at (650) 856-8833 or email us at Sales@StcValve.com.

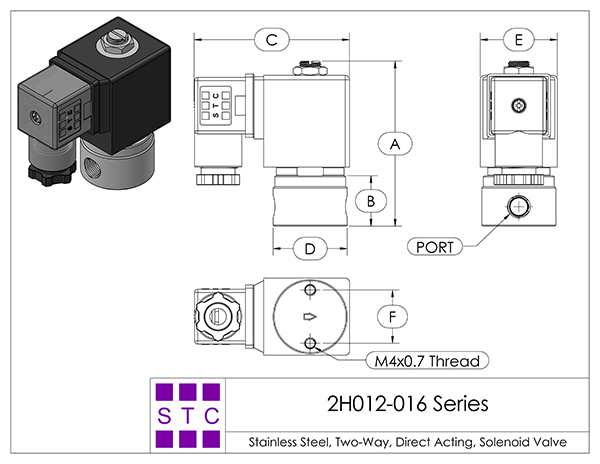

Solenoid Valve Specifications and Dimensions: 2H012-016 Series

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

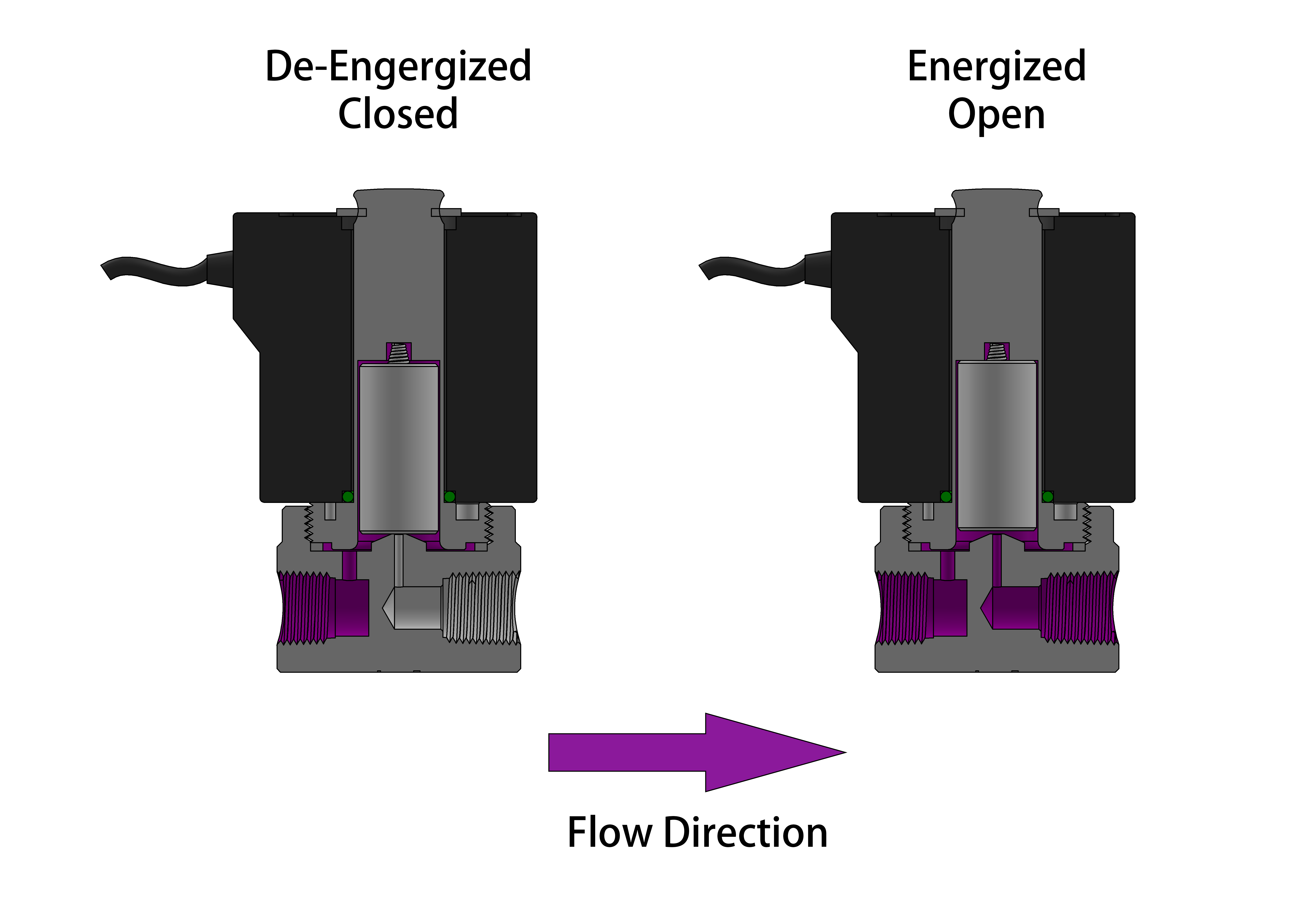

The 2H012-016 valves are direct acting solenoid valves that do not require a minimum

operating differential pressure. As shown in the diagram below, when the coil is de-energized (left diagram),

the plunger rests on the main orifice and is held in place by the plunger spring force, sealing the valve.

When the coil is energized (right diagram), the solenoid lifts the plunger and allows the working medium to

flow through the orifice. The working medium and flow direction are indicated in purple in the diagram.

STC's high performance direct acting plastic body solenoid valves offer reliability, compact and rugged designs, low power consumption, high-speed response, long-life cycle (over 10 million cycles), DIN connections and indicator lights, pre-wired electrical connections, manifold mounting options, and simple installation, maintenance, and control.

Electrical Coil Connections

STC's high performance direct acting plastic body solenoid valves offer reliability, compact and rugged designs, low power consumption, high-speed response, long-life cycle (over 10 million cycles), DIN connections and indicator lights, pre-wired electrical connections, manifold mounting options, and simple installation, maintenance, and control.

| Operation Diagram | ||||||

|

Electrical Coil Connections

- To Connect a DIN Coil:

- Remove the Philips screw from the plastic housting & unplug from the DIN coil.

- Use the removed screw to push the terminal block out of the plastic DIN housing.

- Note the "1", "2", and ground "⏚" symbols.

- For DC DIN Coils, connect "1" to your positive lead and "2" to your negative lead.

- For AC DIN Coils, connect "1" to your HOT lead, "2" to your NEUTRAL lead, and "⏚" to your ground lead, if required.

- To Connect a Grommet Coil:

- For DC Coils, connect the red wire to your positive lead and the black wire to your negative lead.

- For AC Coils, connect the black wire to your HOT lead and the white wire to your NEUTRAL lead.

- For Coils provided with Molded Cables, the color of the wire indicates the type of lead:

- GREEN = Ground Wire

- BLUE = Positive or HOT Wire

- BROWN = Negative or Neutral Wire

| Home | Terms of Use | Terms of Sale | Career | Contact Us | Click Here to Order |

|

Sizto Tech Corporation © 2001-

. All rights reserved. Last modified: February 11, 2019.

Information contained herein may be changed without prior notification. |

|||||